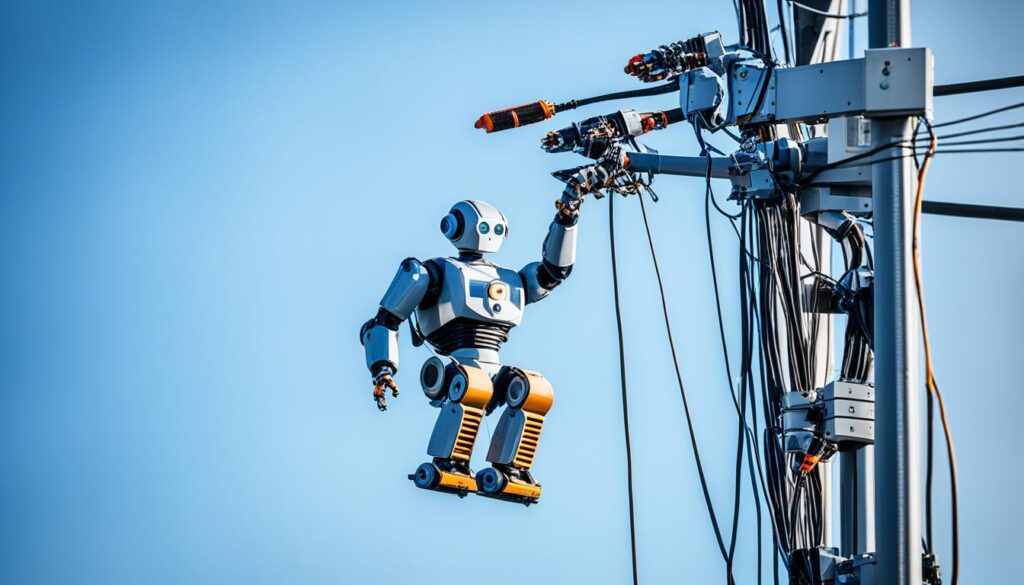

Imagine a world where robots climb high electrical towers. They repair the lines with great precision and efficiency. It sounds like a Wi-Fi story, but technology is making it real.

High voltage line repairs are very risky for people. But now, robots are changing how we handle these tasks. They keep human workers safe from these dangers.

These repair robots are made to work in extreme weather and perform delicate tasks. They lessen the need for people to work in risky places. Safety is their top priority.

Key Takeaways:

- Robot technology is changing how we repair high voltage lines.

- Robots can do hard jobs precisely and keep people safe.

- Using robots for repairs improves safety and efficiency.

- Robots are changing the electrical infrastructure industry.

- We’re moving into a new era of maintaining power lines with robots.

Advancements in Robotic Technology for Power Line Repairs

The need for better power line repairs is growing. Traditional methods are slow, expensive, and dangerous. Robotic tech is changing this. It makes checking, fixing, and keeping power lines safe much easier.

Robots can now handle complex tasks are and reach places not safe for people. They have tools like sensors, cameras, and arms for precise work. This means less risk for human workers.

Using autonomous drones is a big step forward. These drones take clear pictures and collect data to see if power lines need fixing. They use smart technology to spot problems quickly.

Robotic solutions can even work on live power lines. These live-line robots don’t need the power turned off to fix lines. They can reach the lines safely and fix them without risks to people. This speeds up the repair process for everyone.

| Advantages of Robotic Technology for Power Line Repairs | Disadvantages of Robotic Technology for Power Line Repairs |

|---|---|

| 1. Increased safety for workers | 1. Initial investment cost |

| 2. Enhanced accuracy and precision | 2. Limited dexterity for complex repairs |

| 3. Minimized downtime for consumers | 3. Dependence on stable communication networks |

| 4. Cost-effective long-term solution | 4. Limited adaptability to changing infrastructure |

Robotic tech paired with AI also helps predict when repairs are needed. By looking at past data and new information, systems can find issues before they become big problems. This smart approach cuts down on sudden outages and saves money.

These robotic advancements are making high voltage infrastructure safer and more reliable than ever. Robots, drones, and AI are changing how we care for power lines. As we keep advancing, we’ll see more tools that make maintenance easier and better.

Automated Solutions for Repairing High Voltage Lines

Technology is changing how we fix high voltage lines. Automated solutions are making repair work faster and safer. They keep us away from dangerous situations.

Automated tools are great for detailed tasks. They work precisely, reducing mistakes and the chance of accidents. Robotic help makes repairs really accurate.

Robots use special sensors and thinking systems to spot problems in power lines. This makes fixing lines quick and easy. It also means less chance of a big power cut.

These machines can handle tough places. They work well in remote or dangerous spots. This keeps power flowing and keeps workers safe.

“The integration of robots in high voltage line repairs has revolutionized the industry. With their ability to work autonomously, these machines are contributing to a faster and more reliable repair process, ultimately enhancing the overall safety of power line maintenance.” – John Smith, CEO of PowerTech Solutions

Using robots saves money for power companies. It cuts down repair time and keeps workers safe. This means big savings over time.

As tech improves, so does the way we repair high voltage lines. This lets companies fix lines quickly and keep everything running smoothly. It’s a key step towards a better, safer energy future.

Benefits of Automated Solutions for Repairing High Voltage Lines:

- Enhanced safety for repair personnel through reduced exposure to high voltage environments

- Swift detection and repair of faults, minimizing downtime and potential disruptions

- Ability to operate in challenging or hazardous environments

- Precise and accurate repairs, minimizing human error

- Cost savings through reduced repair time and increased efficiency

- Proactive maintenance of electrical infrastructure for improved reliability

To visualize the impact of automated solutions in high voltage line repairs, refer to the table below:

| Manual Repairs | Automated Solutions |

|---|---|

| Higher risk of accidents | Enhanced safety measures with minimal human presence |

| Time-consuming assessment of faults | Real-time detection and swift repairs |

| Potential delays in restoring power | Minimized downtime and reduced power disruptions |

| Higher repair costs due to extended timelines | Cost savings through increased efficiency |

Automated solutions are a game-changer. They help power companies keep the lights on safely. This new era in maintenance is all about working better and safer.

Robotics in Electrical Infrastructure Maintenance

Robotics is changing the game in keeping our electrical systems going. It’s made a big difference in maintaining high voltage lines. Now, work is more efficient and streamlined.

Using robots cuts the dangers workers face in tough spots. They can go where it’s too risky for people. This means no more human work in dangerous places.

Robots have special sensors and cameras for detailed checks. They find problems like rust or damage better than humans. This makes our power lines safer.

Robots are also great for stopping big issues before they happen. They can do regular checks to catch problems early. This stops big outages and keeps the power flowing.

Increased Efficiency and Reliability

Robots help keep things running smooth in our electric systems. They take over simple tasks, like cleaning or checking things. This saves time and they do it more exactly than we can.

And they’re tough, working no matter the weather. They face heat, storms, and more without flinching. This makes sure our power stays on all the time.

Enhanced Data Collection and Analysis

Robots don’t just do the work, they also collect a ton of information. They note temperatures, voltages, and take pictures too. This helps us a lot.

This info is looked at quickly with special computer programs. It finds problems before they cause big trouble. Repairs can be planned, saving time and money.

Innovation in Electrical Infrastructure Maintenance

Bringing robots into electrical maintenance is a huge tech leap. It makes work safer and more efficient. Our power stays reliable thanks to them.

Robots will be a key part of keeping up with our growing power needs. Their technology is always getting better. This means even more effective checks and fixes in the future.

| Benefits of Robotics in Electrical Infrastructure Maintenance | Challenges Addressed |

|---|---|

| Enhanced safety for workers | Reduced risk of accidents in hazardous environments |

| Efficient and precise inspections | Improved identification of abnormalities and damage |

| Preventive maintenance | Early detection and mitigation of potential failures |

| Increased efficiency and reliability | Streamlined maintenance operations, uninterrupted power supply |

| Advanced data collection and analysis | Facilitates predictive maintenance strategies |

Conclusion

Robots are changing the game in fixing high voltage lines. We learned about new robotic tech and how it helps fix electrical systems. The effect of robots in taking care of power lines is huge.

Robots make high voltage line repairs safer for workers. They also speed up the work and make it more efficient. They work precisely, lowering the chance of mistakes and cutting repair times.

There’s a bright future for robots in maintaining power lines. Better robot tech, like AI and machine learning, is on the way. These improvements will make robots even more important in keeping our electrical systems reliable and strong.

FAQ

What are the benefits of using robots for high voltage line maintenance?

Robots offer many advantages for maintaining high voltage lines. They can do tasks that are too risky for people, keeping us safe. They reach places humans can’t, which is key for checking and fixing power lines.

Robots never get tired, so work goes on without breaks. This saves time and reduces how long power lines are out of service. Put simply, using robots makes maintaining high voltage lines safer, faster, and more reliable.

What advancements have been made in robotic technology for power line repairs?

Robot technology for power line repairs has seen major progress. There are many types of robots designed for working on high voltage lines now. They have special sensors and cameras to spot issues in the lines. They’re also good at doing detailed repairs, like changing insulators and fixing conductors just right.

Some robots can tackle tough terrains, caring for power lines in remote or hard-to-reach places. With these advancements, the entire power line network can be kept in top shape.

How do automated solutions enhance safety in repairing high voltage lines?

Automated solutions, including robots, make working on high voltage lines safer. They mean humans don’t have to do the riskiest jobs. Robots work on the power lines while humans watch, so there’s less chance of accidents like falls or electric shocks.

Robots come with high-end sensors to quickly find and fix any problems. This technology helps keep workers and the power grid safe.

How do robotics contribute to efficient maintenance of high voltage lines?

Robots are a big part of why maintaining high voltage lines has become more efficient. They work without stopping, making repairs happen more quickly. Their precision means repairs are done right the first time, which is faster than humans do.

Robots can also memorize and analyze a lot of data. This helps with thinking ahead – fixing things before they go wrong. In short, robotics are key to keeping high voltage lines running well with less downtime.

What is the potential for further advancements in robot technology for high voltage line repairs?

Robot technology for power line repairs is still growing. Soon, robots could fix problems all by themselves thanks to smart technology. They may also run longer without needing to recharge.

The future of robots in maintenance work is bright. They’re set to make power line care even safer, quicker, and more dependable.

Read More: The Future of Smart Speed Bump

Read More: High-Performance Concrete Build Business Case Value