Walking through my neighborhood, I see lots of plastic waste to Bricks on the streets. It shows us the big problem we face with plastic. But, what if we could turn this plastic into something useful? Like Eco-friendly bricks that change the building industry.

Our world loves single-use plastics, but it’s harming our planet. Landfills are full, oceans are filled with plastic, and nature is paying the price. Yet, there’s hope – making plastic waste into durable, eco-friendly bricks. This solution helps solve the plastic pollution crisis and supports sustainable building.

Let’s explore how plastic waste becomes bricks. We’ll look at the challenges, the process, and the benefits of this technology. We’ll see how it’s making our future greener, one brick at a time.

Plastic Pollution: A Global Crisis

Plastic pollution is a big problem that needs urgent action. Every year, over 300 million tons of plastic waste are made. This overloads waste management systems, causing harm to land, water, and oceans.

Environmental Impact of Plastic Waste

Plastic waste has a huge effect on the environment. It can take hundreds of years to break down. While it’s breaking down, it releases harmful chemicals and microplastics into the air, water, and soil.

This pollution hurts ecosystems, animals, and even human health. It can get into our food and water, which is dangerous.

Challenges in Plastic Waste Management

Managing plastic waste is a big challenge. Many places don’t have good waste collection and recycling. Not knowing about the problem and not teaching people about it makes it worse.

Also, plastic waste is complex and needs special ways to be processed. This makes it hard to solve the plastic pollution issue.

We need a big effort from governments, industries, and communities to fix this. We must focus on reducing waste, recycling better, and finding eco-friendly alternatives. This is key to a sustainable future.

“The health of our planet and the health of our communities are inextricably linked. We must take action to address the plastic pollution crisis for the sake of both.”

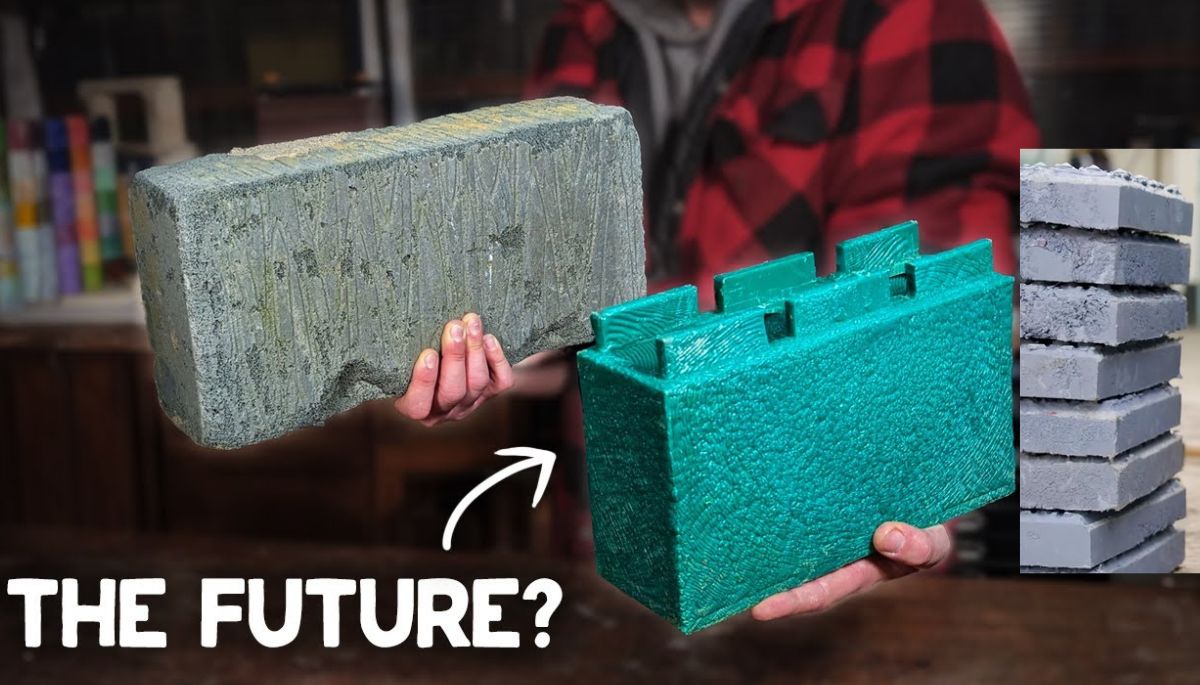

Innovative Solution: Recycled Plastic Bricks

People are finding a great way to deal with plastic pollution – turning waste plastic into building materials. Recycled plastic bricks are becoming a green choice for building, changing the construction world.

Recycled plastic bricks are made by melting and shaping waste plastic. They are strong and last a long time. This method keeps plastic out of landfills and oceans and is cost-effective and eco-friendly for building sustainable buildings.

This process shows how the circular economy works. It turns waste-to-resource. This is a big step towards solving the global plastic problem and promoting sustainable building practices.

Recycled plastic bricks have many benefits. They are durable, lightweight, and water-resistant, perfect for many building projects. Making these bricks also uses less energy than traditional bricks, which helps reduce carbon emissions.

The rise of recycled plastic bricks gives us hope for a cleaner future. This new solution tackles plastic pollution and supports a circular and eco-friendly future in building.

Plastic Waste to Bricks: The Process

Turning plastic waste into eco-friendly bricks is a new way to tackle the global plastic pollution problem. It uses advanced recycling tech to make a green building material from plastics we throw away.

Sorting and Cleaning Plastic Waste

The first step is sorting and cleaning the plastic materials. This is key to making sure the plastic is clean and ready for recycling.

- Careful sorting by plastic type and color to optimize the recycling process

- Thorough cleaning and decontamination of the plastic waste

- Removal of any non-plastic materials or foreign objects

Melting and Molding Plastic Bricks

After cleaning, the plastic is melted and molded into bricks. This makes a strong, lasting building material from plastics.

- Heating the plastic waste to its melting point

- Molding the molten plastic into the desired brick shape

- Allowing the plastic bricks to cool and solidify

This method creates a top-notch, green building material. It’s great for homes, businesses, and infrastructure.

This recycling tech turns plastic waste into something valuable. It’s a green solution to plastic pollution and helps move towards a circular economy.

Benefits of Plastic Brick Construction

Plastic bricks bring many advantages to sustainable building projects. They are known for their durability and strength and cost-effectiveness. These materials are changing the way we build things.

Durability and Strength

Plastic bricks are very durable and strong. They are made from recycled plastic waste. This makes them resistant to weather, wear, and tear.

They don’t rot, rust, or get damaged by insects. This makes them a great choice for many construction needs.

Cost-Effectiveness

Plastic bricks are also a smart choice because they are cost-effective. Using recycled plastic lowers production costs. This means builders can save money without losing quality or performance.

This makes plastic bricks a top pick for builders who want to save money and use sustainable building materials.

Plastic bricks offer more than just durability and cost savings. They help reduce the environmental impact of building by using plastic waste that would otherwise end up in landfills or oceans. This supports a more circular and sustainable economy.

Eco-Friendly Building Materials

The world is now more aware of how construction affects the environment. This has led to a big increase in the use of eco-friendly building materials. These materials support sustainable construction and a move towards a circular economy.

Recycled plastic bricks are a great example of these materials. They are made from plastic waste that would otherwise harm the environment. Using them helps solve the plastic pollution problem and lowers the construction industry’s carbon footprint.

| Eco-Friendly Building Materials | Benefits |

|---|---|

| Recycled Plastic Bricks | Diverts plastic waste from landfills and oceans Durable and long-lasting construction material Cost-effective compared to traditional building materials |

| Bamboo | Renewable and rapidly renewable resource High strength-to-weight ratio Biodegradable and environmentally friendly |

| Hempcrete | Carbon-negative material that absorbs more CO2 than it emits Excellent thermal insulation properties Mold and pest-resistant |

Using these eco-friendly materials cuts down on construction’s environmental harm. It also helps move towards a sustainable and circular economy. As the construction world adopts these new solutions, we can hope for a future. A future where buildings are made with care for the environment and smart use of resources.

“The future of construction lies in the embrace of sustainable, eco-friendly building materials that prioritize environmental responsibility and resource efficiency.”

Sustainable Construction: A Growing Trend

The construction world is changing fast. More people want buildings that are good for the planet. This change is because of growing awareness about the environment, the need to lessen our carbon footprint, and a focus on being responsible.

Green Building Certifications

Green building certifications are a big part of this change. Certifications like LEED and BREEAM show that a building is good for the environment. They are becoming more popular in the construction world.

These programs check if buildings use less energy, save water, pick materials wisely, and have good air inside. Builders and developers get certified to show they care about the planet and building in a responsible way.

| Certification | Focus Areas | Adoption Rate |

|---|---|---|

| LEED | Energy efficiency, water conservation, material selection, indoor air quality | Widely adopted globally, with over 100,000 certified projects as of 2021 |

| BREEAM | Energy, water, waste, pollution, transport, materials, land use, ecology, health and wellbeing | Prominent in Europe, with over 560,000 certified projects as of 2021 |

More people are choosing green building certifications. This shows the construction industry’s push for sustainability and its aim to lessen its environmental impact.

“Sustainable construction is not just a trend, it’s a necessity. As we strive to create a more environmentally responsible future, the construction industry has a crucial role to play in leading the way.”

Plastic Waste to Bricks: Real-World Applications

The technology to turn plastic waste into strong bricks is changing the game in sustainable building. It’s being used in eco-friendly buildings and waste reduction projects. This new method is making a big impact in the construction world.

In Bangalore, India, an affordable housing project used recycled plastic bricks. This project offered cheap and green homes. It also kept a lot of plastic out of landfills, showing how effective this new material is.

Austin, Texas, in the U.S., is also using this tech for a new community center. By choosing plastic waste bricks, the project cuts down on environmental harm. It also shows how this solution can be versatile in making eco-friendly buildings.

| Project | Location | Benefits |

|---|---|---|

| Affordable Housing Complex | Bangalore, India | Sustainable housing, waste reduction |

| Community Center | Austin, Texas, USA | Eco-friendly construction, waste diversion |

These examples show how plastic waste to bricks is changing the construction world. It offers sustainable construction projects and innovative building materials. These address the big problem of plastic pollution.

“The use of recycled plastic bricks in construction projects is a game-changer, providing a practical solution to the plastic waste crisis while creating eco-friendly and resilient buildings.”

The need for waste reduction solutions and eco-friendly buildings is growing. So, the use of plastic waste to bricks is likely to get even more widespread. This could lead to a greener future for building projects.

Circular Economy Initiatives

The world is facing big challenges with plastic pollution. New solutions that follow a circular economy are becoming more popular. Turning plastic waste into things like bricks is key to reducing waste and using resources better.

Waste Reduction and Resource Efficiency

Turning plastic waste into bricks shows how a circular economy works. It keeps plastic out of landfills and turns it into something useful. This helps reduce waste and is good for the planet.

Also, making bricks from recycled plastic means we use less raw materials. This is great for resource efficiency and saving resources. It helps lessen the harm plastic does to the environment. Plus, it helps make building things more sustainable.

“Circular economy initiatives are crucial in tackling the global plastic crisis. By transforming waste into valuable resources, we can create a more sustainable future.”

Using recycled plastic bricks in building is a real example of the circular economy. This idea helps reduce waste and protect the environment. It also means we use less of the earth’s natural resources.

- Diversion of plastic waste from landfills

- Repurposing plastic waste into building materials

- Reduced demand for virgin raw materials

- Promotion of sustainable construction practices

- Contribution to the principles of a circular economy

This article has shown how using recycled plastic can change the game in building and waste management in the U.S. We’ve looked at the big problem of plastic pollution and its bad effects on our planet. It also talked about the challenges we face in dealing with plastic waste.

Recycled plastic bricks are a great example of turning waste into something useful. They help us build a better future by reducing landfill and water pollution. These bricks are strong, last a long time, and are cheaper than traditional building materials.

As we move towards a greener future, using plastic waste for bricks is a key step. By supporting circular economy and green building, we can make a big difference. This approach turns waste into a valuable resource, helping us create a world where waste isn’t a problem.

Read More: The Future of Smart Speed Bump

Read More: High-Performance Concrete Build Business Case Value