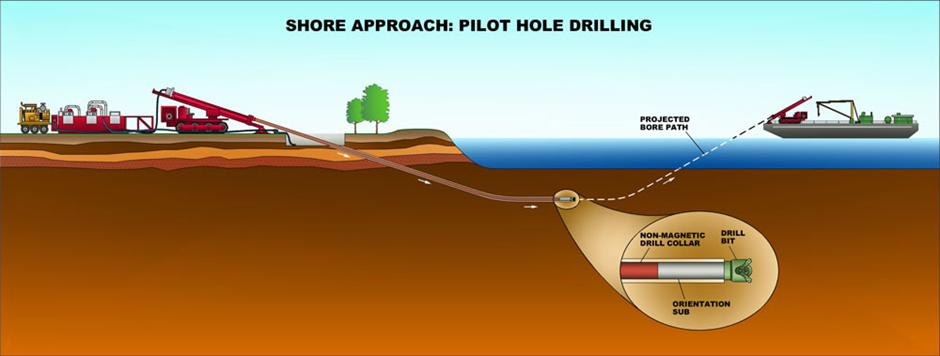

A trenchless method for constructing underground cables, pipes, and service conduit is called horizontal directional drilling (HDD). It entails precisely drilling along the selected bore path and back reaming the necessary pipe using a directional drilling machine and related equipment.

Directional drilling is a three-stage process:

PILOT HOLE

Drilling a pilot hole with a modest diameter is the first step. High pressure jets and the drill bit will grind the soils ahead of the drill stem as drilling fluid is fed through the drill pipe to the drill bit. The drilling fluid will also transport the drilling waste back to the drill rig’s entry pit. Depending on the size and intricacy of the shot, there are many methods for tracking the pilot hole. A walkover guiding system is used for smaller pictures while a wire line magnetics type system is used for larger, more intricate shots. In all cases, the drill stem’s precise coordinates are sent to the location engineer through a transmitter or steering tool that is placed close to the drill head. Continuous readings are obtained to monitor the drill head’s depth, alignment, and % slope.

The operator and locator will make adjustments to maintain the pilot hole on the planned bore route. Depending on the soil’s current state and the amount of steering needed, the pilot hole’s pace will change. When you get to the exit location, you separate the beacon housing and bit and put a reamer in its place.

PRE-REAMING

The pilot hole must then be pre-reamed and enlarged to a size that will allow the product lines to be installed safely. In order to cut and remove particles and widen the hole, a reamer is pushed back and rotated as drilling fluid is pumped. The number of cuttings taken from the hole and the current soil conditions will both influence the pre-reaming pace.

A clean and stable hole will be created using bentonite and other chemicals. During pre-reaming, bentonite is used to make a “cake layer” around the outside of the hole. This will aid in preventing fluid loss or infiltration and stabilizing the bore hole. Clay soils are made easier to break up by the use of additives like polymers. Any clogs inside the bore hole will be avoided by a drilling fluid that is more uniformly mixed.

PIPING BACK

The retraction of the pipe into the previously reamed hole is the last phase. To avoid any torsional stress from the revolving drill string being passed to the product pipe, the drill rod and reamer will be coupled to a swivel, which is used between the product line and the reamer. Drilling fluid is poured deep into the earth to lubricate the product pipe as it is drawn into the drill hole.