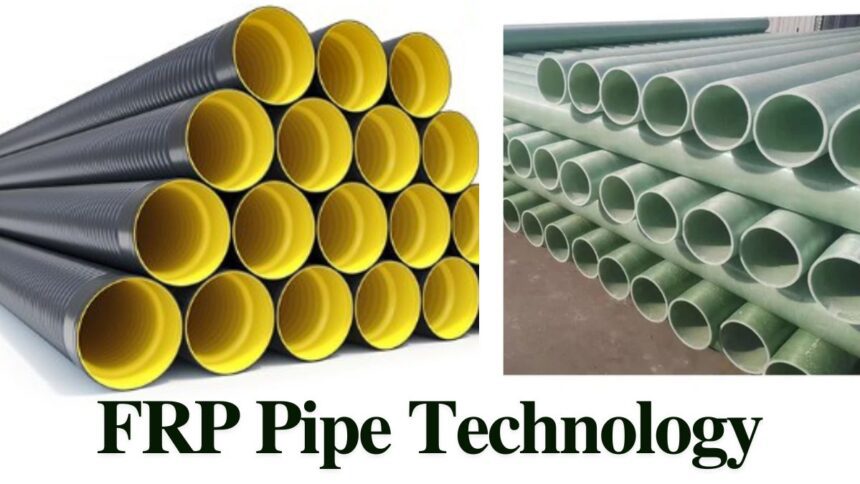

FRP Pipe Technology

Fiber Reinforced Plastic FRP Pipe Technology has emerged as a groundbreaking solution in industries requiring durable, lightweight, and corrosion-resistant piping systems. FRP pipes, made from composite materials, are becoming increasingly popular due to their remarkable properties and wide-ranging applications. Whether in water supply, chemical transport, or infrastructure projects, FRP pipes are revolutionizing the way industries handle fluid transportation.

This article explores the fundamentals of FRP pipe technology, its manufacturing processes, key features, applications, advantages, challenges, and future prospects.

What is FRP Pipe Technology?

FRP pipe technology involves the use of composite materials to manufacture pipes that are strong, lightweight, and resistant to environmental and chemical degradation. FRP pipes are primarily made from a polymer matrix reinforced with glass fibers. The combination of these materials ensures exceptional mechanical strength and durability while maintaining flexibility and lightweight properties.

Manufacturing Process of FRP Pipes

The production of FRP pipes involves several advanced techniques, ensuring their superior performance:

1. Filament Winding

- A widely used process where continuous glass fibers are wound onto a rotating mandrel in specific patterns. The fibers are impregnated with resin to create a composite structure, providing excellent strength and durability.

2. Centrifugal Casting

- In this method, glass fibers and resin are poured into a spinning mold. Centrifugal force ensures even distribution and compaction, creating pipes with uniform thickness and enhanced structural integrity.

3. Pultrusion

- A continuous manufacturing process where glass fibers are pulled through a resin bath and then through a heated die to form pipes. This method is ideal for creating pipes with consistent cross-sectional shapes.

4. Hand Lay-Up

- A manual process where glass fibers are layered with resin on a mold. While labor-intensive, this method allows for custom shapes and sizes.

Key Features of FRP Pipes

1. Corrosion Resistance

- FRP pipes are highly resistant to corrosion, making them suitable for transporting chemicals, seawater, and other corrosive substances.

2. Lightweight

- These pipes weigh significantly less than traditional materials like steel or concrete, simplifying transportation and installation.

3. High Strength-to-Weight Ratio

- Despite being lightweight, FRP pipes offer excellent mechanical strength, enabling them to handle high pressures and loads.

4. Durability

- The combination of glass fibers and resin ensures a long service life, even in harsh environments.

5. Low Maintenance

- The pipes require minimal maintenance, reducing operational costs over their lifespan.

6. Customization

- FRP pipes can be manufactured in various sizes, shapes, and thicknesses to meet specific project requirements.

Applications of FRP Pipe Technology

FRP pipes are used across a wide range of industries due to their versatility and performance:

1. Water and Wastewater Management

- Ideal for potable water distribution, sewage systems, and wastewater treatment plants due to their corrosion resistance and durability.

2. Chemical and Petrochemical Industries

- FRP pipes are widely used to transport corrosive chemicals, acids, and gases, ensuring safe and efficient operations.

3. Oil and Gas Industry

- In offshore and onshore applications, FRP pipes are used for transporting crude oil, natural gas, and other hydrocarbons.

4. Power Generation

- Cooling water systems, ash handling, and flue gas desulfurization systems in power plants benefit from the reliability of FRP pipes.

5. Marine and Offshore Applications

- FRP pipes are used in desalination plants, ballast water systems, and offshore platforms due to their resistance to seawater corrosion.

6. Infrastructure Projects

- From irrigation systems to drainage networks, FRP pipes play a vital role in infrastructure development.

Advantages of FRP Pipe Technology

The growing adoption of FRP pipe technology can be attributed to its numerous advantages:

1. Extended Lifespan

- FRP pipes are designed to last for decades, even in challenging environments, reducing replacement costs.

2. Energy Efficiency

- The smooth internal surface of FRP pipes reduces friction, minimizing energy consumption during fluid transport.

3. Cost-Effective Installation

- Lightweight and easy to handle, FRP pipes reduce installation time and labor costs.

4. Versatility

- Suitable for a wide range of applications, from industrial to residential projects.

5. Environmental Resistance

- The pipes can withstand extreme temperatures, UV exposure, and chemical attacks, ensuring reliable performance.

6. Safety

- Non-toxic and leak-proof, FRP pipes are safe for transporting drinking water and other sensitive materials.

Challenges and Limitations

Despite their advantages, FRP pipes face certain challenges:

1. High Initial Cost

- The manufacturing process and raw materials make FRP pipes more expensive upfront compared to traditional options.

2. Specialized Installation

- Proper installation requires trained personnel and specialized equipment, adding to the overall cost.

3. Limited Temperature Range

- While resistant to moderate heat, extreme temperatures can affect the performance of FRP pipes.

4. Mechanical Damage

- Although durable, FRP pipes can be vulnerable to impacts and scratches, which may compromise their structural integrity.

5. Recycling Challenges

- The composite nature of FRP materials makes recycling difficult, raising environmental concerns.

Innovations in FRP Pipe Technology

Continuous research and development efforts are driving advancements in FRP pipe technology:

1. Improved Resin Formulations

- New resin types are being developed to enhance temperature resistance and mechanical strength.

2. Smart Monitoring Systems

- Integrating sensors into FRP pipes allows real-time monitoring of pressure, temperature, and flow rates, ensuring efficient operations.

3. Hybrid Composites

- Combining FRP with other materials, such as carbon fibers, increases performance in specialized applications.

4. Sustainable Practices

- Efforts are being made to create recyclable FRP materials, addressing environmental concerns.

5. Automation in Manufacturing

- Advanced manufacturing techniques are reducing production costs and improving consistency in quality.

Future Prospects

The future of FRP pipe technology looks promising as industries increasingly prioritize sustainability and efficiency. Key trends include:

1. Wider Adoption Across Industries

- As costs decrease, more industries are expected to adopt FRP pipes for diverse applications.

2. Integration with Renewable Energy Projects

- FRP pipes are likely to play a crucial role in renewable energy projects, such as wind farms and solar power plants.

3. Enhanced Durability

- Research into nanotechnology and advanced materials will further improve the lifespan and performance of FRP pipes.

4. Global Expansion

- The demand for infrastructure development in emerging economies will drive the growth of the FRP pipe market.

Conclusion

FRP pipe technology is transforming the piping industry by offering durable, lightweight, and corrosion-resistant solutions. Its applications span across industries, from chemical transport to infrastructure development, proving its versatility and value.

While challenges remain, continuous innovation and advancements in manufacturing processes are addressing these issues, paving the way for wider adoption. As industries strive for efficiency, sustainability, and reliability, FRP pipe technology stands out as a vital component of modern infrastructure and industrial systems.

Read More: The Future of Smart Speed Bump

Read More: High-Performance Concrete Build Business Case Value