In today’s fast-paced construction world, efficiency and safety are no longer optional—they are essential. As steel structures become more complex and project timelines tighter, engineers and contractors are turning toward smarter connection systems that simplify construction without compromising strength. One such innovation gaining widespread attention is field-bolted HSS moment connections.

Hollow Structural Sections (HSS) are already valued for their clean aesthetics, high strength-to-weight ratio, and structural efficiency. When combined with field-bolted moment connections, they offer a practical solution that aligns perfectly with modern construction demands. From high-rise buildings to industrial facilities and seismic zones, these connections are reshaping how steel frames are assembled on site.

What Are Field-Bolted HSS Moment Connections?

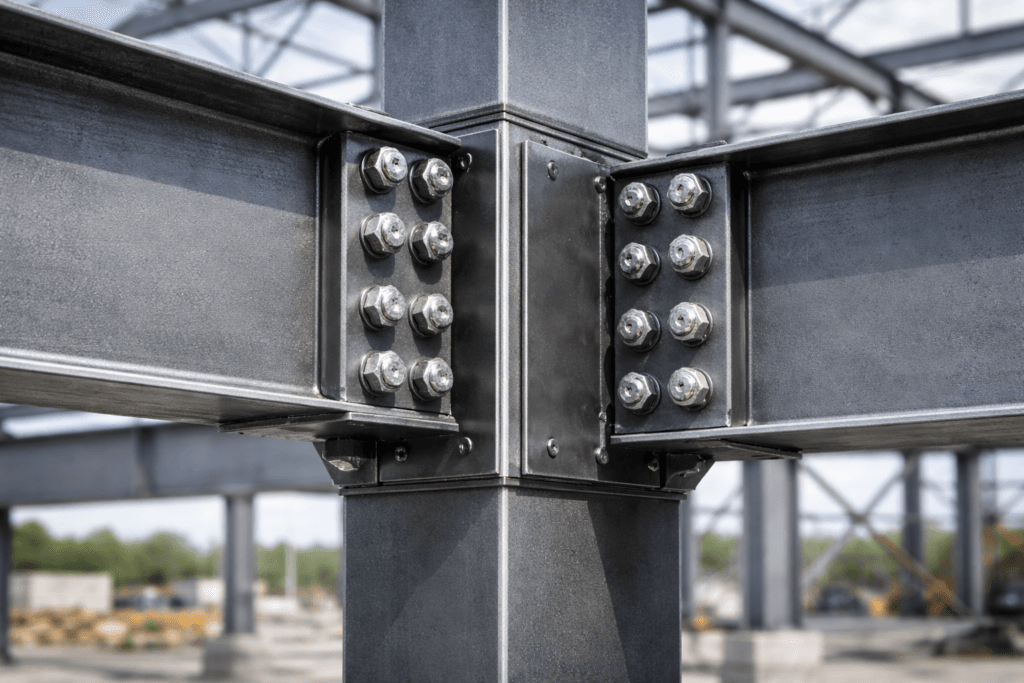

Field-bolted HSS moment connections are structural steel connections that transfer bending moments between beams and columns using bolts instead of on-site welding. These connections are typically prefabricated in controlled shop environments and assembled at the construction site using high-strength bolts.

The result is a moment-resisting connection that provides rigidity and load transfer while significantly reducing site complexity. This approach is especially useful when working with HSS columns, where traditional welding can be difficult, time-consuming, and risky.

Why the Construction Industry Is Moving Away from On-Site Welding

On-site welding has long been a challenge in steel construction. Weather conditions, limited access, quality control issues, and safety risks often make welding unpredictable and expensive. Field-bolted connections address these issues directly.

By shifting most fabrication work to the shop and limiting site activity to bolting, contractors gain better control over quality while keeping projects on schedule. This shift is not just about convenience—it’s about building smarter and safer.

Key Advantages of Field-Bolted HSS Moment Connections

1️⃣ Ease of Installation

One of the biggest advantages is simple and straightforward installation. Since components arrive pre-fabricated, crews can assemble them quickly using standard bolting tools. This is especially beneficial on congested sites or projects with limited working space.

Even in challenging environments such as urban construction zones or elevated structures, bolted connections make assembly more manageable and predictable.

2️⃣ Significant Time Savings

Time is money in construction, and field-bolted HSS moment connections help save both. Compared to welded connections, bolted systems dramatically reduce erection time.

There’s no need to wait for weld inspections, cooling periods, or rework due to poor weld quality. Crews can move faster, schedules become more reliable, and project milestones are easier to achieve.

3️⃣ Cost-Effective Construction Solution

Reducing welding also reduces costs. Field-bolted connections lower expenses related to skilled welding labor, specialized equipment, safety monitoring, and inspection procedures.

Additionally, faster erection translates into reduced crane time and lower overall project overheads. For large steel projects, these savings can be substantial.

4️⃣ Improved Safety on Site

Construction safety is a top priority, and minimizing on-site welding directly reduces risks. Welding introduces hazards such as fire, fumes, burns, and exposure to extreme heat.

Field-bolted HSS moment connections significantly improve safety by eliminating many of these dangers. Bolting operations are cleaner, quieter, and safer, creating a better working environment for construction crews.

5️⃣ Versatility Across Structural Applications

These connections are highly adaptable and can be used in a wide range of structural configurations. Whether it’s commercial buildings, industrial plants, warehouses, or seismic-resistant structures, field-bolted HSS moment connections offer flexibility without compromising performance.

They can accommodate different beam sizes, column geometries, and architectural layouts, making them suitable for both functional and visually demanding projects.

6️⃣ Long-Term Durability and Performance

When properly designed and installed, field-bolted HSS moment connections provide excellent long-term performance. High-strength bolts and engineered connection plates ensure reliable load transfer and resistance to fatigue.

In seismic regions, these connections can be detailed to provide ductility and energy dissipation, enhancing the structure’s ability to withstand earthquakes. With proper corrosion protection and maintenance, they offer durability comparable to traditional welded systems.

Engineering Considerations for HSS Moment Connections

Designing effective field-bolted HSS moment connections requires careful engineering. Load paths, bolt pretension, plate thickness, and connection geometry must all be considered to ensure structural integrity.

Engineers often rely on advanced analysis methods and design guides to optimize these connections for both strength and constructability. The goal is to balance performance with ease of installation—something field-bolted systems excel at.

Applications in Modern Construction

Field-bolted HSS moment connections are increasingly used in:

- High-rise commercial buildings

- Industrial facilities and plants

- Seismic-resistant structures

- Architectural steel frameworks

- Renovation and retrofit projects

Their ability to simplify erection while maintaining structural performance makes them especially attractive for fast-track and design-build projects.

A Future-Ready Connection System

As construction continues to evolve, the demand for efficient, safe, and cost-effective solutions will only grow. Field-bolted HSS moment connections represent a forward-thinking approach that aligns with these priorities.

They combine the strength and aesthetics of HSS with the practicality of bolted assembly, offering a solution that works for engineers, contractors, and project owners alike.

Read More: The Future of Smart Speed Bump

Read More: High-Performance Concrete Build Business Case Value