Track to Perfection

Modern railways are the backbone of transportation infrastructure around the world. Whether moving freight or people, trains rely on a strong foundation for safe and efficient travel. At the core of this foundation lies an often-overlooked component: the ballast. And to keep this crucial layer in optimal condition, one specialized tool leads the charge — the Rail Ballast Cleaning Machine.

In this article, we’ll break down everything you need to know about this powerful piece of railway equipment, why it matters, and how it plays a vital role in rail system maintenance and performance.

What Is Rail Ballast?

Before diving into the machine itself, let’s understand what ballast is. Rail ballast consists of crushed stones placed beneath and around railway tracks. It serves several essential functions:

- Stability: Keeps tracks in place under heavy loads.

- Drainage: Prevents water accumulation that can damage track beds.

- Load Distribution: Absorbs vibrations and spreads train load evenly.

- Weed Control: Limits plant growth around tracks.

Over time, however, ballast can become contaminated with dirt, dust, and broken rock fragments. When this happens, its effectiveness drops, leading to unsafe conditions and costly repairs.

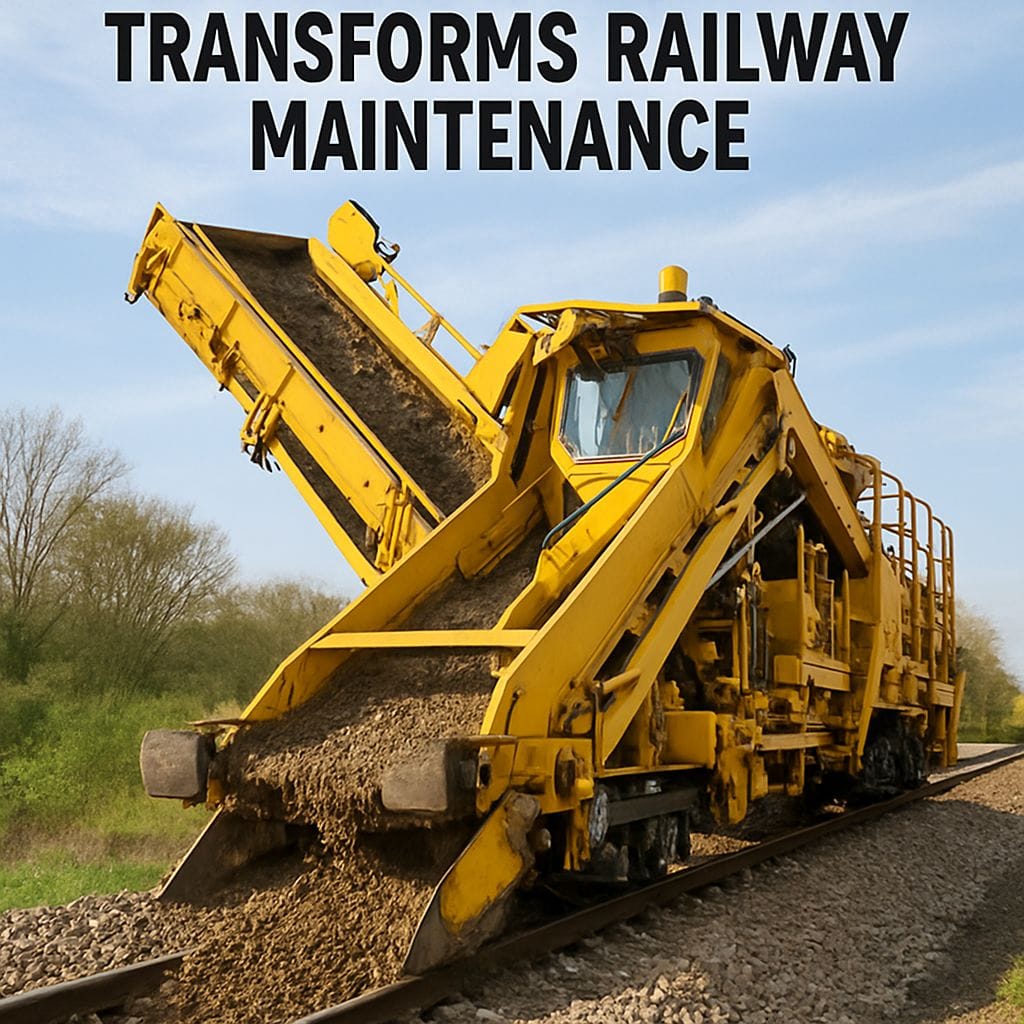

Enter the Rail Ballast Cleaning Machine

A Rail Ballast Cleaning Machine is a specialized piece of equipment designed to clean and rejuvenate the ballast bed without removing the track. It sifts, separates, and removes contaminated materials while redistributing cleaned ballast back onto the rail bed.

This process ensures better track stability, improved drainage, and extended service life of the railway infrastructure — all without dismantling the rails.

How Does a Ballast Cleaning Machine Work?

These machines are engineering marvels that combine multiple functions in one seamless operation. Here’s a simplified breakdown of how they work:

1. Excavation

The machine lowers a cutter chain or excavator under the rail to scoop out the old, dirty ballast.

2. Screening and Cleaning

The extracted material is passed through a vibrating screen system. This separates fine particles, dust, and debris from reusable stones.

3. Waste Removal

Non-reusable waste (called “fines”) is moved away using conveyors and dumped into accompanying wagons or off to the side of the track for later collection.

4. Ballast Reapplication

Clean ballast is returned under the track, while new ballast can be added to ensure optimal depth and coverage.

Some machines are even equipped with integrated tamping units that re-align and stabilize the track after cleaning — making them a one-stop solution.

Why Ballast Cleaning Matters More Than Ever

Rail networks carry heavier and faster trains today than ever before. With increased load comes increased stress on tracks. Dirty or compacted ballast compromises drainage, causing track deformation, water pooling, and even derailment risks.

Here’s why regular ballast cleaning is critical:

- Safety: Maintains proper track geometry and alignment.

- Cost-Efficiency: Extends the lifespan of tracks and sleepers.

- Performance: Enhances train speed potential by ensuring track integrity.

- Environmental: Reduces the need for total ballast replacement and associated waste.

Types of Rail Ballast Cleaning Machines

Depending on the rail system and maintenance needs, various types of ballast cleaning machines are used:

1. Continuous Ballast Cleaners

Ideal for long rail sections, these machines can clean ballast without stopping the train traffic for extended periods.

2. Spot Cleaners

Used for cleaning specific problem areas, such as water-logged sections or high-wear zones.

3. High-Output Cleaners

Used on major railway lines, these are capable of cleaning several kilometers in a single shift. They’re often part of integrated track maintenance trains.

4. Urban or Light Rail Cleaners

Compact machines designed for light rail systems and city tracks with limited space.

Notable Manufacturers in the Industry

Several global companies are known for building high-quality ballast cleaning machines:

- Plasser & Theurer (Austria): Industry leaders offering a wide range of high-output machines.

- Loram Maintenance of Way (USA): Known for innovative rail maintenance equipment.

- Matisa (Switzerland): Offers precision-focused machines for European railways.

- Harsco Rail (USA): Supplies versatile ballast maintenance solutions globally.

Each manufacturer designs machines tailored to different track types, budgets, and operational needs.

Key Features to Look For

If you’re in charge of procurement or planning maintenance, here are some features that define a modern rail ballast cleaning machine:

- High cleaning efficiency: Speed and accuracy in removing fines.

- Track-lifting system: Maintains rail position during cleaning.

- Integrated tamping tools: For realignment and compacting post-cleaning.

- Waste management system: Efficient handling of unusable debris.

- Operator comfort and safety: Enclosed cabins, automated controls, and real-time diagnostics.

The Future of Rail Ballast Maintenance

As rail networks modernize, the demand for smarter, faster, and more efficient ballast cleaning technology continues to grow. Future innovations may include:

- AI-driven performance analytics

- Automated self-diagnosing machines

- Eco-friendly waste disposal systems

- GPS-guided precision cleaning

With such innovations, railway systems can expect fewer disruptions, better safety records, and lower maintenance costs.

Conclusion: Clean Ballast, Safe Journey

The role of a Rail Ballast Cleaning Machine in modern railway operations cannot be overstated. It’s not just about cleaning rocks — it’s about ensuring that the entire rail system runs smoothly, safely, and sustainably.

Regular ballast cleaning with the right machinery prevents problems before they occur. It saves time, reduces repair costs, and most importantly, protects lives by keeping tracks in peak condition.

So next time you see a train gliding smoothly over the rails, remember: there’s a quiet hero behind the scenes — the ballast cleaner that made the ride possible.

Read More: The Future of Smart Speed Bump

Read More: High-Performance Concrete Build Business Case Value